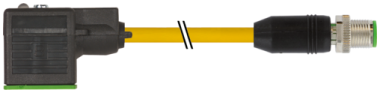

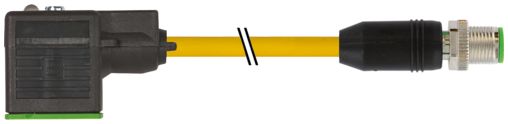

M12 male 0° A-cod. / MSUD valve plug A-18mm

PUR 4x0.75 ye UL/CSA+drag ch. 1.5m

| Art.No.: | 7000-41911-0370150 |

| Alternative product: | |

| Weight: | 0.134 kg |

| Country of origin: | CZ |

Contact Us for Availability

Description

Form A (18 mm)

Further cable lengths on request.

Male M12

straight

12...30 V DC

4-pole

Z-Diode + LED

Control current

Switching frequency

Plastic housings with good resistance against chemicals and oils.

Technical Data

| Cable length | 1,5 m |

|---|

Side 1

| Tightening torque | 0,4 Nm |

|---|---|

| Mounting method | inserted, screwed |

| Coating contact | silver-plated |

| Family construction form | MSUD |

| Thread | M3 |

| Material contact | Copper alloy |

| Material | PUR |

| No. of poles | 4 |

Side 2

| Tightening torque | 0,6 Nm |

|---|---|

| Mounting method | inserted, screwed |

| Coating contact | gold plated |

| Family construction form | M12 |

| Thread | M12 x 1 |

| Material contact | Copper alloy |

| Material | PBT |

| No. of poles | 4 |

| Width across flats | SW13 |

Electrical data | Supply

| Operating voltage DC min. | 12 V |

|---|---|

| Operating voltage DC max. | 30 V |

| Cut-off peak voltage max. | 46 V |

| Operating current per contact min. (40 °C) | 0,1 A |

| Operating current per contact max. (40°C) | 2 A |

| Current consumption max. | 6 mA |

Diagnostics

| Status indication LED | yellow |

|---|

Device protection | Electrical

| Degree of protection (EN IEC 60529) | IP67 |

|---|---|

| Additional condition protection degree | inserted, screwed |

Electrical data | Output

| Switching frequency max. | 50 Hz |

|---|

Mechanical data

| Contour for corrugated hose | without |

|---|

Mechanical data | Material data

| Coating locking | Nickeled |

|---|---|

| Color housing | black |

| Material gasket | PUR |

| Material housing | Plastic |

| Locking material | Zinc die-casting |

Mechanical data | Mounting data

| Mounting method | inserted, screwed |

|---|

Important installation notes

| Note on strain relief | Protect the connectors by suitable measures from mechanical loads, e.g. by the usage of cable ties. |

|---|---|

| Note on bending radius | Attention: Observe the permissible bending radii when laying cables, as the IP protection class can be endangered by excessive bending forces. |

Conformity

| Product standard | DIN EN 61076-2-101 (M12) |

|---|

Cable data

General data | Cable

| Cable identification | 037 |

|---|---|

| Cable Type | 3 |

| Printing color of wire insulation | white (isolation black) |

| Jacket Color | yellow |

| Type of Certificate | cURus |

Structure | Cable

| Amount stranding | 1 |

|---|---|

| Stranding | 4 wires twisted |

| wire arrangement | black 1, black 2, black 3, green-yellow |

Mechanical data | Cable

| Cable weigth | 69,3 g/m |

|---|---|

| Material jacket | PUR |

| Shore hardness jacket | 90 ± 5 Shore A |

| Freedom from ingredients (jacket) | lead-free, cadmium-free, CFC-free, halogen-free, silicone-free |

| Outer-diameter (jacket) | 6,5 mm |

| Tolerance outer diameter (sheath) | ± 5 % |

| Material wire insulation | PP |

| Amount wires | 4 |

| Outer diameter insulation | 1,85 mm |

| Outer diameter tolerance core insulation | ± 5 % |

| Shore hardness wire insulation | 70 ± 5 Shore D |

| Ingredient freeness wire insulation | lead-free, cadmium-free, CFC-free, halogen-free, silicone-free |

| Printing color of wire insulation | white (isolation black) |

| Amount strands (wire) | 42 |

| Diameter of single wires | 0,15 mm |

| Conductor crosssection (wire) | 0,75 mm² |

| Material conductor wire | Stranded copper wire, bare |

| Conductor type (wire) | strand class 6 |

| Traversing distance (C-track) | 10 m @ 25 °C | horizontal |

Electrical data | Cable

| Nominal voltage AC max. | 300 V |

|---|---|

| Current load capacity (standard) | to DIN VDE 0298-4 |

| Current load capacity min. wire | 9,6 A |

| Electrical resistance line constant wire | 26 Ω/km @ 20 °C |

| AC withstand voltage (wire - wire) | 2,5 kV @ 60 s |

| Power frequency withstand voltage (wire - jacket) | 2,5 kV @ 60 s |

Temperature range | Cable

| Min. operating temperature (static) | -40 °C |

|---|---|

| Max. operating temperature (fixed) | 80 °C / 90 °C @ 10000 h Operation |

| Operating temperature min. (dynamic) | -25 °C |

| Operating temperature max. (dynamic) | 80 °C / 90 °C @ 10000 h Operation |

Resistances | Cable

| Flame resistance | UL 1581 § 1100 FT2 | IEC 60332-2-2 | UL 1581 § 1090 |

|---|---|

| chemical resistance | Good, application-related testing |

| Gasoline resistance | Good, application-related testing |

| Oil resistance | DIN EN 60811-404 | Good, application-related testing |

Installation | Cable

| Bending radius (fixed) | 5 x Outer diameter |

|---|---|

| Bending radius (dynamic) | 10 x Outer diameter |

| No. of bending cycles (C-track) | 10 Mio. @ 25 °C |

| No. of torsion cycles | 2 Mio. |

| Torsion speed | 35 cycles/min |

| Torsion stress | ± 180 °/m |

Commercial data

| ECLASS-6.0 | 27143423 |

|---|---|

| ECLASS-6.1 | 27279218 |

| ECLASS-7.0 | 27279218 |

| ECLASS-8.0 | 27279218 |

| ECLASS-9.0 | 27060312 |

| ECLASS-10.1 | 27060312 |

| ECLASS-11.1 | 27060312 |

| ECLASS-12.0 | 27060312 |

| ETIM-5.0 | EC001855 |

| customs tariff number | 85444290 |

| GTIN | 4048879143455 |

| Packaging unit | 1 |

Accessories

---- Cable Marker ----

---- Marking Accessories ----

---- Torque Wrench ----